ZF Aftermarket product portfolio

Whether dual-mass flywheel or XTend: ZF Aftermarket supplies OE quality SACHS clutches and clutch components designed for greater cost-effectiveness of car clutch replacement or repair and added driver comfort.

SACHS clutch systems

Reliable and powerful

Hill starts, endless traffic jams and winding roads – clutches for passenger cars are subject to a wide variety of demands every day. SACHS clutches in OE quality get car drivers into gear easily. They ensure great convenience and are particularly reliable. SACHS clutches for passenger cars are also convincing due to their long service life.

Fast installation, highest quality: the SACHS Clutch kit with DMF and XTend.

In addition to high-quality individual products, SACHS offers a number of practical installation kits. They simplify assembly and provide convincing advantages: If a clutch needs to be replaced in a vehicle, it is recommended that all relevant components be replaced in order to make sure that all parts work together well. This ensures optimum transmission reliability of the torque at engine clutch to the transmission and the longest possible service life of all clutch components.

Innovative technology in a clutch kit

The practical clutch kit with DMF and XTend is the first choice when a clutch needs to be replaced. The clutch kit includes all spare parts required by the mechanic – in the usual high quality of SACHS, of course. The SACHS dual-mass flywheel offers the following advantages:

- High noise quality

- Excellent vibration damping throughout the entire speed range

The advantages of the XTend clutch pressure plate of SACHS are:

- Insensitive to extreme temperatures, soiling and aging

- Consistent pedal forces for the entire service life

- Axial installation space reduction

The clutch kit with DMF and Xtend is also available as a clutch kit with differential-before-clutch assembly.

Replacing the clutch in record time

Compared to individual products, the clutch kit with DMF and XTend offers a variety of convincing advantages:

- Quick ordering – the right parts with an order number

- Easy assembly through the inclusion of several components in one box

- Everything from a single source, providing you with components that work together perfectly

- Optimal durability due to the quality and expertise of SACHS

You will also receive more clutch kit combinations from SACHS, such as with the concentric slave cylinder CSC.

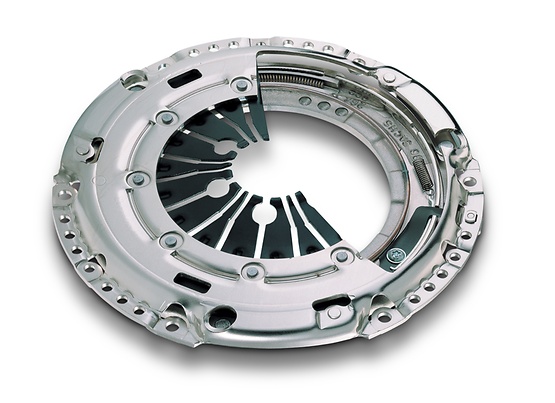

XTend clutch pressure plate for passenger cars

Even the highest-quality and most durable car clutch is subject to operational wear and tear. This is where the technology of the XTend clutch pressure plate made by SACHS comes in: It provides automatic wear compensation. How it works: The XTend clutch pressure plate for passenger cars separates facing wear from the movement of the diaphragm spring.

The compensation mechanism constantly registers reduction in the lining and compensates for the clearance by reliably turning an adjustment ring. This keeps the clutch from being vulnerable to extreme temperatures, soiling and aging. Furthermore, the pedal-force conditions remain constant over the entire service life. At the same time, the service life is extended, since the facing can continue to be worn. Another advantage of XTend is in its design: The installation space required axially in the clutch system with operational wear is reduced through the use of XTend.

Pilot bearing for passenger cars

The pilot bearing, also referred to as the guide bearing, is predominantly responsible for the functioning of the passenger-car clutch. As a ball bearing, it guides the transmission input shaft and is thus predominantly responsible for the functioning of the clutch in the passenger car. If wear results in an angular offset, the shaft is no longer properly supported, which may lead to clutch defects. SACHS offers passenger-car pilot bearings for all common vehicle models. When replacing the clutch, the pilot bearing should always be inspected and, if required, replaced as well.

Differential before clutch for passenger cars

DBC stands for differential before clutch and means that a transmission input shaft is mounted in front of the dual-mass flywheel (DMF). This requires what is known as a drive plate, a transfer plate that ensures that the transmission input shaft has enough space. There are many advantages of a high-quality SACHS DBC: It provides outstanding vibration damping over the entire speed range and effectively reduces noise. Moreover, it is largely unaffected by extreme temperatures, soiling or wear and features high durability.

DBC is used in particular in vehicles with an engine installed longitudinally and front-wheel drive. It is available with dual-mass flywheels (DMF), a DMF module and practical clutch kits that include all the components for a clutch replacement. The installation of a DBC is easy using the included special tool: SACHS provides the relevant installation instructions.

Vibration reduction in all speed ranges: the SACHS Dual-mass flywheel for passenger cars

The SACHS dual-mass flywheel (planetary DMF) is the key to first-class passenger car and light commercial vehicle drivability. The driver and occupants are aware of reduced driveline and body noise and enjoy smoother travel with more pleasant gear shifts.

The use of advanced and multi-functional components enables the SACHS dual-mass flywheel to be installed also in the compact car class.

SACHS dual-mass flywheels are installed as standard features in many vehicles and have the following advantages:

- Isolated engine vibrations

- Reduced noise

- Prevent transmission damage

- Improved shifting comfort

- Quieter start-up behavior

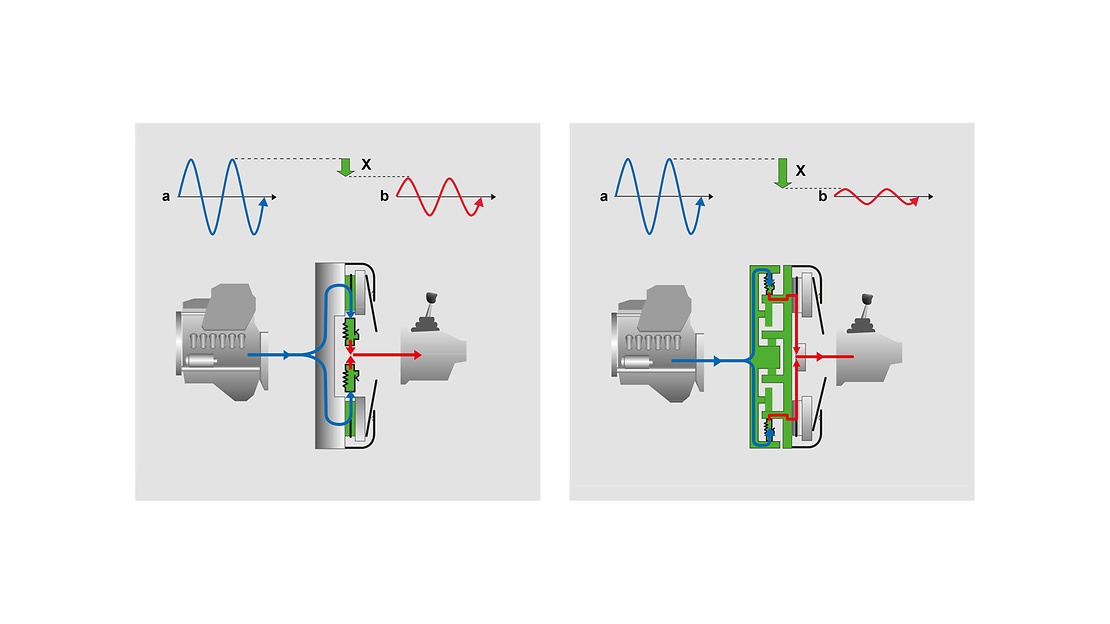

Effective reduction of engine vibrations

SACHS dual-mass flywheels for cars and SACHS dual-mass flywheels for LCV are designed in a way that engine vibrations are largely reduced in all speed ranges. SACHS engineers develop car dual-mass flywheels according to the specifications of the vehicle manufacturers.

The following diagrams show the improved vibration characteristics when using a SACHS dual-mass flywheel. (a: engine vibrations, b: transmission vibrations, X: damping)

Helping the environment: SACHS fan clutches for passenger cars

Intelligent high-tech fan clutches or viscous clutches from SACHS reduce the fan speed by switching the fan on or off in the vehicle depending on the current cooling requirements. In this way the SACHS fan clutch for passenger cars reduces annoying noise and helps to save fuel.

With a low engine load, the head wind often suffices to dissipate the waste heat from radiator and engine. For cooling, a low fan speed or even zero fan speed is sufficient.

With rising temperature in the engine compartment and decreasing speed, there is an increasing risk of overheating and heat accumulation in the engine or vehicle. For example, this is the case when climbing hills or in stop-and-go traffic. Now the SACHS fan clutch for passenger cars is activated and the fan allows sufficient air to flow through the radiator. This engine cooling system is fast and effective.

How the SACHS fan clutch for passenger cars works

For more than 30 years, SACHS has been providing intelligent fan clutches for nearly every vehicle model. They are located in the vehicle directly behind the radiator. In this way they can check the current cooling requirements and draw in additional air through the radiator if necessary.

The center of the SACHS viscous clutch for passenger cars consists of light-alloy multidisks, which generate the largest possible surface area. There is a bimetallic spring on this surface. If the radiator becomes too hot, this surface heats up, including the spring. The bimetallic spring opens a valve, ensuring that viscous liquid is pumped into the working chamber. This makes it possible to adjust the speed of the fan or the fan impeller as required. If the radiator temperature drops again, the bimetallic spring closes the valve, ensuring that the viscous liquid is pumped out of the working chamber and that the fan or the fan impeller is reduced to the speed required for the temperature.

More comfort - less fuel: SACHS passenger car torque converters

The torque converter is a key component in any automatic transmission: it aids starting and takes on the job of the conventional clutch by disengaging and engaging the engine and transmission. It is the interaction between the engine with its mechanical kinetic energy and the torque converter with its hydraulic energy generated by special oil that gives the transmission the capacity for automatic driving.

SACHS hydrodynamic torque converters for passenger cars can be adjusted as required to the drivelines of vehicles with automatic transmissions. They guarantee perfect launch behavior and optimum driving comfort, even on poor roads or in traffic jams. What’s more, they provide high dynamics at low fuel consumption.

The combination with a SACHS torque converter lock-up clutch - also called lock-up clutch - boosts these positive properties to an even higher level. The torque converter lock-up clutch consists of a lock-up clutch and torsional dampers. It offsets power losses caused by incomplete torque transmission in the coupling area. Furthermore, it guarantees especially efficient power transmission, prevents wear during the launch process and cuts energy loss as well as noise.

Packing an extra punch for torque converter transmissions: SACHS Twin TD twin Torsional damper

As this video shows, the SACHS torque converter for passenger cars can also be equipped with the new TwinTD twin torsional damper.

This advanced damping system minimizes torsional vibrations that increasingly occur in vehicles with modern engines and correspondingly small engine displacement that reach high torques even at low speeds. Thanks to the minimized torsional vibrations with the TwinTD, earlier shift points are possible.

The result: improved driving comfort especially at low engine speeds, and thereby significantly reduced fuel consumption.

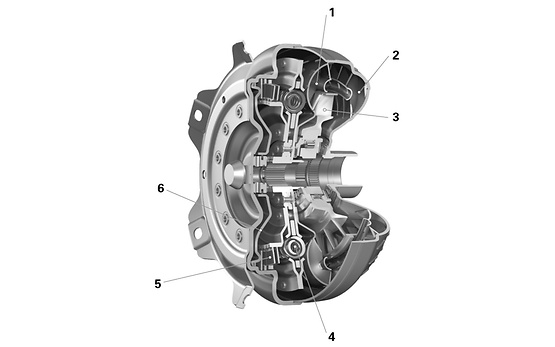

Efficient construction - individual settings

Its extremely compact size means the hydrodynamic torque converter for passenger cars packs high performance into a small installation space. Also, the effective cooling capability of the lock-up clutch optimizes heat dissipation and ensures low wear.

Another advantage of SACHS lock-up clutches is their intelligent modular design: A selection from two, four or six possible friction surfaces with different hydraulic circuit diameters enables individual tuning so they can be adapted to meet various driveline designs.

The major components are:

- Turbine wheel (1)

- Impeller (2)

- Stator (3)

- Torsional damper (4)

- Brake lining (5)

- Lock-up clutch (6)

Benefits of a SACHS torque converter

- Excellent decoupling of rotational irregularities in the driveline

- High efficiency for start-up and shift operations

- Early closing of the torque converter clutch

- Minimized weight and moment of inertia

- Optimized hydrodynamics

- Significantly lower consumption and CO2 emissions

Clutch Actuation Systems for Passenger Cars

The clutch actuation system is installed in automobiles and comprises all components with which the power is transferred from the pedal to the clutch release bearing in order to release the clutch. The pedal travel is transferred mechanically (usually via a cable pull) or hydraulically. SACHS supplies various types of passenger car clutch actuation systems.

Concentric slave cylinder (CSC)

The concentric slave cylinder (CSC) merges the clutch release bearing and the slave cylinder to form an integrated unit. As a result, the release fork between the clutch release bearing and slave cylinder and the respective bearing points are not required. Assembly takes place directly on the transmission.

This is advantageous compared to conventional release systems: Vibrations and grabs during launch are prevented as the number of mechanical components has been reduced. The driver benefits from the best possible ride comfort.

The concentric slave cylinder (CSC) should be replaced with each clutch repair in order to prevent delayed signs of wear and, consequently, further repairs.

As concentric slave cylinders are now installed as standard in approximately half of all vehicle models, SACHS also offers clutch kits with CSC.

Further information on SACHS clutch kits

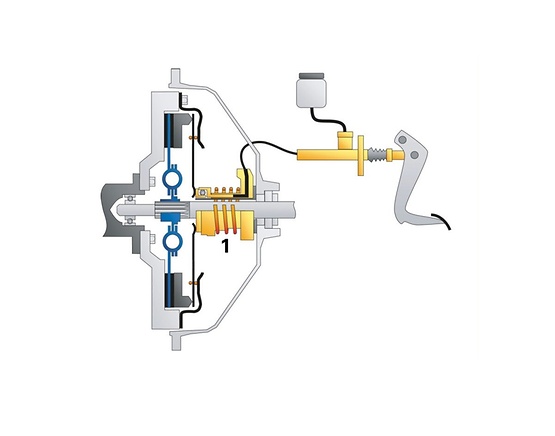

Function of a hydraulic release system with CSC

The concentric slave cylinder (CSC) (1) is assembled directly on the transmission.

The diaphragm-spring clutch can be set free of clearance, i.e., the release bearing is constantly running whilst the clutch is turning. A preload generated by the actuation system ensures that the clutch and the release bearing thrust ring are running at the same speed. Speed differences would lead to the generation of noises and increased wear.

The release bearings are self-centering (can be radially adjusted by approx. 1.5 mm) in order to compensate for alignment tolerances between the diaphragm spring and the clutch release bearing thrust face. They centrically adjust to the diaphragm spring tongues automatically during the first clutch actuations.

CSC clutch release bearings are used when the installation space is not large enough for a conventional clutch actuation system.

Master and slave cylinders

The clutch actuation system transfers the pressure of the driver’s foot on the pedal to the clutch in order to disengage it. It has to ensure absolute reliability, meet ergonomic requirements and provide a high level of comfort throughout its entire service life. The actuation system includes the hydraulic transmission path with master and slave cylinder as well as the mechanical part with clutch release bearing and lever.

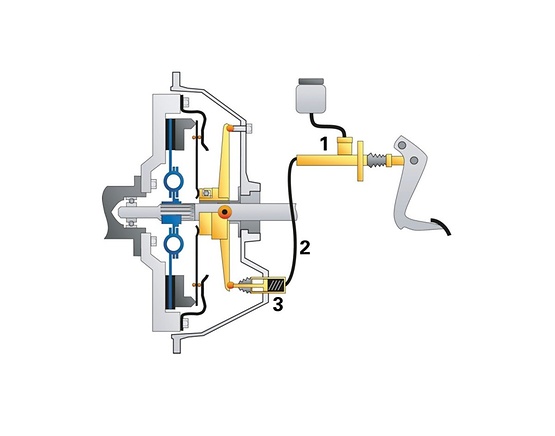

Function of the master/slave cylinder

The clutch actuation is transferred hydraulically in systems equipped with a master/slave cylinder. The pedal motion is transferred to a hydraulic cylinder (1, master) located directly below the pedal. In a closed system, the cylinder generates hydraulic pressure that is absorbed by a slave cylinder (3) via a hose assembly (2).

In order to ensure ideal functionality, it is possible to bleed the clutch actuation system.

High-quality SACHS clutch cables

With its high-quality clutch cables, SACHS covers the European vehicle market almost completely. Clutch cables are subject to high mechanical stress. The first indications of wear are increased physical effort and noises when actuating the clutch, or clutch slipping and grab.

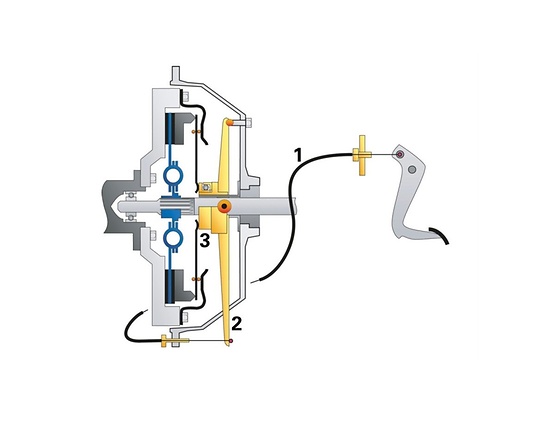

Function of the clutch actuation system with cable control

The clutch actuation is transferred purely mechanically via clutch cables. The pedal motion is transferred to a steel cable (1), the release fork (2) and the clutch release bearing (3) so that the clutch is actuated. The highlighted areas show wearing zones in the clutch environment.

![[pro]Academy [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)